17

C U R I O S I T Y - D R I V E N

R E S E A R C H @ H K U S

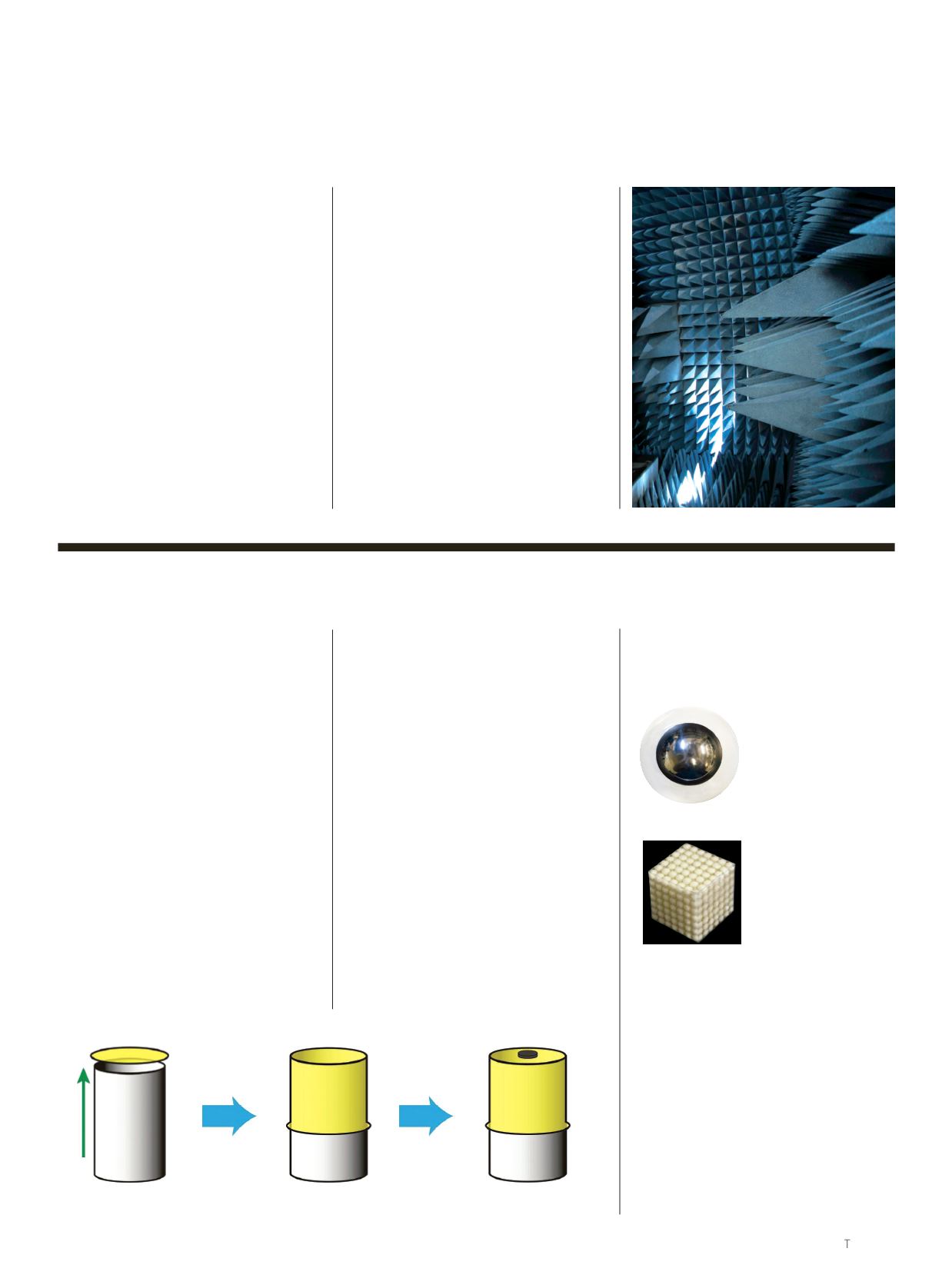

Each resonant unit

has a low frequency

resonance of

400Hz and some

higher resonance

frequencies.

Resonant units

assembled as a sonic

crystal – for example,

a cubic structure,

as shown. Sonic

transmission exhibits

a sonic gap at 400Hz.

Locally resonant sonic materials, designed

to reflect sound waves at pre-specified

frequencies by local resonance.

The HKUST team came at these problems

by employing the physics law of local reso-

nance and trialing rudimentary novel ma-

terials that might have the same impact on

sound waves. Eventually, they created an

exciting new composite that did just that.

The first HKUST publication on the

findings appeared in

Science

in 2000. It

was met with acclaim by the media. But

not so readily accepted by those in the

acoustics field. “Many people thought we

were wrong: ‘How can someone come

from nowhere and think of something

new’,” Prof Sheng said. Despite the skep-

ticism of some in the acoustics world,

the HKUST team continued their studies

and experimentation. Gradually, through

continuous research, major strides were

achieved.

In place of a wall of extremely heavy

material to bounce back sound, the

researchers created a thin, lightweight

membrane-type acoustic metamaterial,

capable of breaking the mass density

law for frequencies of 150Hz to 1,000Hz

by around 200 times. While it seemed

counterintuitive to think of stopping low

frequency sound with a thin membrane,

it was in fact due to the membrane’s

“flimsiness” that this could be achieved

at low frequencies. Even in a small finite

sample with boundaries defined by a

rigid grid, there could be low-frequency

oscillation patterns. With the addition of

a small mass, or “button”, at the center

of the membrane sample, the vibrational

eigenfrequencies could be tuned, and at

the frequency between two eigenmodes

where the vibration amplitude was zero,

the result was almost complete reflection.

Stage One:Wave Reflection

Blocking Low Frequency Sound

The question that set the HKUST team on

its way was: is it possible to find an acous-

tic material with properties that enabled

it to shield any kind of sound wave, in-

cluding the difficult low frequency ranges

of 400Hz and below? Metal was known

to play a special role in manipulating

low frequency electromagnetic waves.

But no such class of materials existed for

acoustics.

Low frequency noise is stubbornly hard

to shield from due to its long wavelength,

which gives it greater penetration than

high frequency noise. Using conventional

mass density laws, this means that it takes

four times the mass to screen out a low

frequency sound of 200Hz than to attenu-

ate an 800Hz noise to the same degree.

Now think of trying to block a noise. To

stop noise going from one area to another,

several materials would usually be

combined to reflect or absorb different

frequencies. However, using conventional

methods (reflection-based solid materials),

it would take five centimeters of materials

(aluminum, mass density 2,700kg/m) to

attenuate 100Hz by 40dB. Such methods

would thus require materials too thick

to be practical for low-frequency appli-

cations. To absorb low frequency sound

would require structure as shown to the

right. They are bulky and not practical for

everyday applications.

Conventional sound

absorbing materials

Push the tube against

the membrane

Membrane tightened

Circular mass is attached

to center of membrane

These sonic materials demonstrated they

were tunable when different materials,

sizes and geometry of the basic unit were

used. They could screen out specific

frequencies over a range of 150Hz to

1,000Hz.

The thickness of materials could also be

reduced. Acoustic metamaterial units are

a factor of 10 to 100+ smaller than the

relevant wavelengths. Thus, the

metamaterial could be thin and small,

and still manipulate and attenuate low

frequency sound.